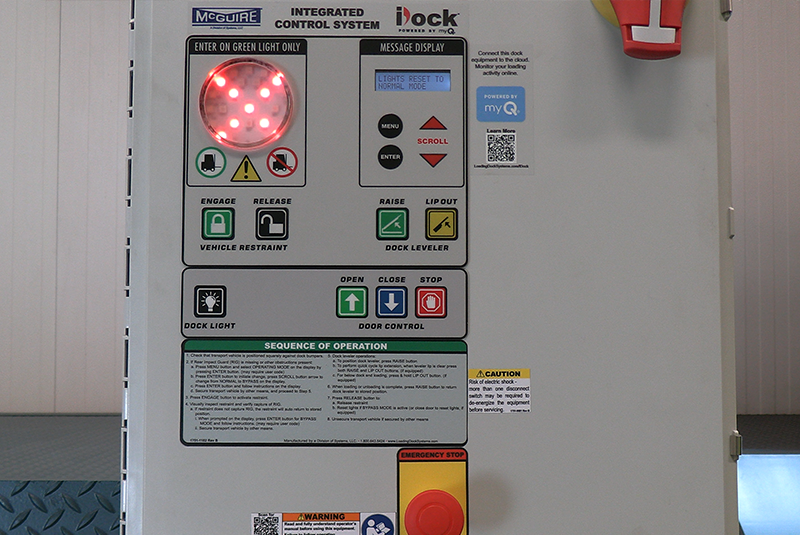

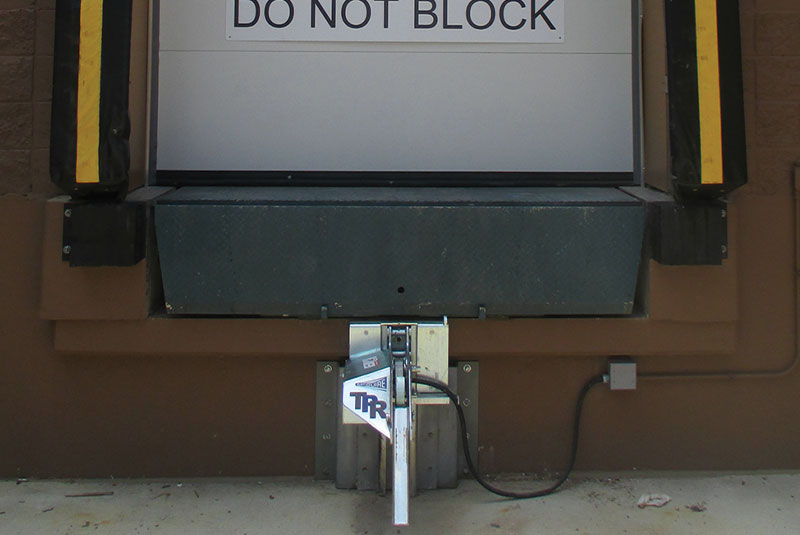

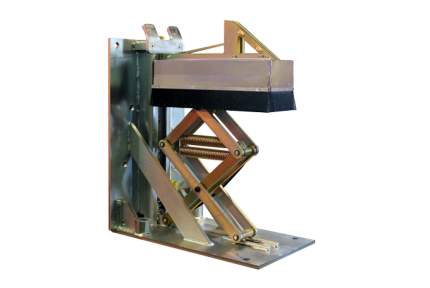

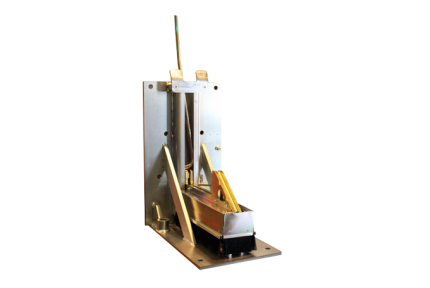

TPR® Automatic Vehicle Restraint

Loading Dock Truck Restraint

The McGuire TPR® truck-positioned vehicle restraint is designed to automatically position itself and secure a trailer’s rear impact guard (RIG) to reduce the likelihood of premature trailer separation during the loading/ unloading process.

The TPR® is designed to withstand a pulling force in excess of 32,000 lbs and has a service range of 4” to 10” horizontally from the face of the dock bumpers and 9” to 30” vertically above the drive approach. The integral motor, gear, and brake assembly are specifically designed for the TPR®. The TPR® vehicle restraint is highly adaptable to new or existing loading docks.

Category: Vehicle Restraints

PRODUCT DOCUMENTS

PRODUCT DOCUMENTS

Related products

Stop-Tite Automatic Vehicle Restraint

Automatic Loading Dock Truck Restraint

The Stop-Tite® AAL (automatic operation, automatic lights) vehicle restraint is operated with push button activation (115V/1PH). It comes equipped with a RIG sensor bar that notifies dock workers if the restraint's arm is not securely engaged with the trailer's Rear Impact Guard.

The Stop-Tite has a low profile, non-impact design for wall or driveway mount. The remote power pack allows the choice of mounting location. It can be mounted next to the restraint, on the outside wall away from the backing trailer, inside a leveler pit, or positioned inside the building for ease of service. An override selector switch, automatic light sequencing of the red/green inside/outside lights, and available interlock terminals are all designed with safety in mind.

The Stop-Tite® AAL comes with a protective debris guard and a Zinc dichromate finish. It features a full one (1) year base warranty on all structural, hydraulic, and electrical components. It also meets all current NHTSA regulations.

Stop-Tite Manual Vehicle Restraint

Manual Loading Dock Truck Restraint

The Stop-Tite® M, MML & MAL are all manually activated vehicle restraints via an operating handle. They have a low profile, non-impact design for wall and driveway mount. All three (3) types have a protective debris guard and a Zinc dichromate finish.

The M version is manual operation and signs only. The MML version is a manual operation and a manually operated communication system changed via a selector switch on an internal control panel that sequences the red/green inside/outside lights. The MAL version comes equipped with switching that will automatically sequence the inside/outside red/green lights. The light communication packages can also be upgraded to the optional iDock Controls with an interactive message display. The MAL also has a RIG sensor bar that notifies dock workers if the restraint's arm is not securely engaged with the trailer's Rear Impact Guard. All three (3) versions feature a full one (1) year base warranty on all structural, hydraulic, and electrical components.

TPR UniLock® Automatic Vehicle Restraint

Loading Dock Truck Restraint

The TPR UniLock® is the only trailer-positioned vehicle restraint that can automatically remove "RIG Wedge" pressure. RIG Wedge is caused when the trailer is pushed forward during loading/unloading and the trailer's Rear Impact Guard (RIG) applies so much pressure to the restraint's hook that the truck driver must reverse the trailer in order to release the restraint. The UniLock has an advanced cam design that first rotates the hook away from the RIG to remove the pressure and then rotates down to a stored position.

The UniLock vehicle restraint also has an internal safety mechanism that locks the restraint's hook in place when pressure is applied, maintaining a secure engagement. This makes it universally effective on any obstructed Rear Impact Guard (RIG), including intermodal trailers with cover plates that prevent the restraint's hook from latching on top of the RIG.

The UniLock is designed to withstand a pulling force in excess of 32,000 lbs and has a service range of 4” to 10” horizontally from the face of the dock bumpers and 9” to 30” vertically above the drive approach. The integral motor, gear, and brake assembly are specifically designed for the UniLock. The UniLock vehicle restraint is highly adaptable to new or existing loading docks.

UniChock™ Vehicle Restraint

Wheel-Based Vehicle Restraint

The UniChock™ is a wheel-based trailer restraint with advanced light communication and is available as a standalone unit or integrated with other dock equipment. This universally effective chock helps prevent unexpected trailer departure or movement from the loading dock during the loading process.

Once a trailer is fully backed and parked in position against the dock bumpers, the UniChock is removed from the storage bracket and placed under the front of one of the trailer’s back tires. This will sound an audible indicator and display a message on the iDock Controller that the unit is in a safe position. The dock attendant can then proceed to open the door and deploy the leveler.

The UniChock is equipped with advanced safety features. In addition to the controller message display and light communication, If the chock is moved to an unsafe position during loading, an audible alarm will sound until the restraint is back in the correct position.

After loading is complete, the dock attendant stores the leveler and closes the overhead door, which will then sound and display indications to return the UniChock to the storage bracket.

UXL Vehicle Restraint

Wheel-Based Vehicle Restraint

The UXL is a wheel-based trailer restraint with advanced light communication. Package available as a standalone unit or integrated with other dock equipment. This universally effective chock helps prevent unexpected trailer departure or movement from the loading dock during the loading process.

Once a trailer is fully backed and parked in position against the dock bumpers, the UXL is taken from the stored position and placed under the front of one of the trailer’s back tires on the track. This will display a message on the iDock Controller that the unit is in a safe position. The dock attendant can then proceed to open the door and deploy the leveler.

The UXL is equipped with advanced safety features. In addition to the controller message display and light communication, If the chock is moved to an unsafe position during loading, an audible alarm will sound until the restraint is back in the correct position.

After loading is complete, the dock attendant will store the leveler and close the overhead door; the control box will then display indications to return the UXL to the storing position.