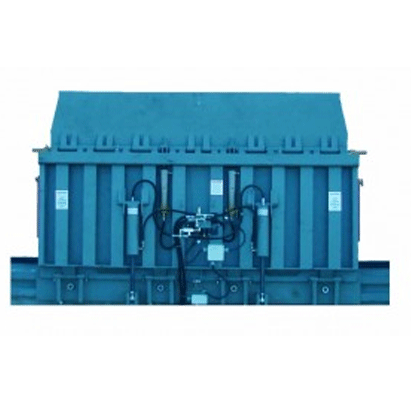

Container Ramps

Container Ramps

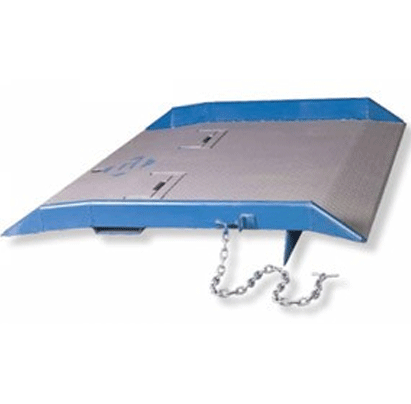

The Container Ramp is designed for safe and efficient loading and unloading of shipping containers, allowing a seamless transition from ground level to the container bed. Built for rugged use, it ensures stability, durability, and reliability in heavy-duty environments.

Categories: Dock Boards, Dock Levelers

Description

Description

Specifications:

- Strength & Durability: Built tough to withstand heavy use

- Security: Full-width stiffener provides strength and a secure fit against the container

- Locking Mechanism: Locking chains with a specially designed keeper for firm attachment

- Ease of Use: Quick and simple chain adjustment with a sturdy grab notch bracket

- Capacity Options: Available in 15K, 20K, 25K, and 30K capacities (custom sizes available)

- Compliance: Manufactured and tested to meet ANSI Standard MH30.2

Related products

“HP” SERIES STANDARD DUTY HYDRAULIC

Pit Style Hydraulic Dock Leveler

The HP Series hydraulic dock leveler is designed with dependability and toughness in mind for your medium to lighter duty applications. The “HP” offers the same easy push button smooth, consistent operation as the heavy duty H series and the same built in safety, durability and toughness. Easy clean out and servicing are features of all McGuire levelers. Your budget, your safety and trouble free service are always number one with McGuire. They are also most often mounted in a pre-formed pit at the dock commonly used to reduce the grade between the dock floor and the trailer bed. Various sizes and capacities allow for a large amount of flexibility. Hydraulic levelers have added safety features and save time in operation and maintenance.

This series comes in 6’, 6’6” & 7’ standard widths and 6’, 8’ & 10’ standard lengths with 12’ and other lengths available. Standard capacities are 25K, 30K, 35K and 40K CIR (Comparative Industry Rating).

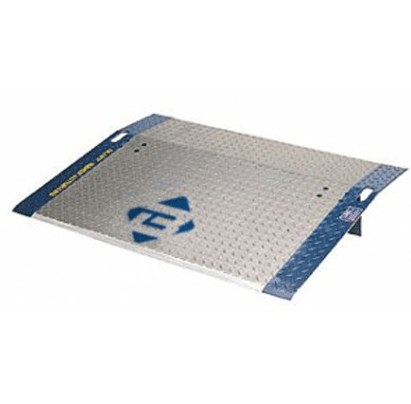

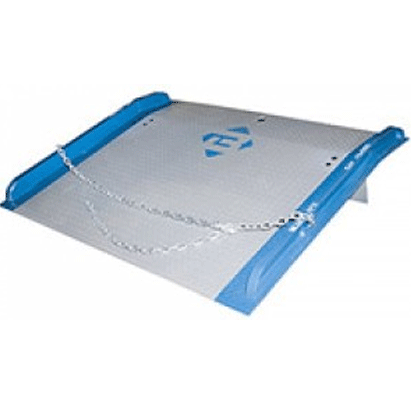

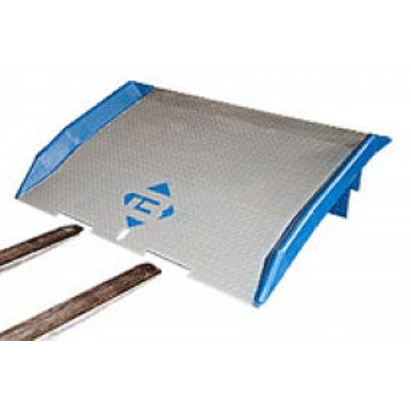

Aluminum Walk Ramps – Apron Style

Aluminum Walk Ramps – Apron Style

Lightweight, Portable, and Built for Safety

Bluff’s Aluminum Walk Ramps—apron Style—offer a strong yet lightweight solution for efficiently loading and unloading cargo. Designed for portability and convenience, these ramps are perfect for warehouses, delivery services, and industrial settings.

Edge of Dock Leveler E66R & E72R

Smooth Building-To-Truck Transition

- Designed to minimize bumps, gaps and damage to cargo and material handling equipment

- Reduces shocks and jolts to workers

- Facilitates fast movement of material handling equipment and forklifts

- Handle is easy to push/pull for comfortable and fast operation

- Handle range of motion keeps workers in a comfortable position

- Reduces bumps and trip hazards on deck and lip

- Rugged construction of lip and deck hinge provides durability for years of service

- Lip hinge sheds debris minimizing trapping and grinding between the lip deck junction causing fatigue

- Textured powder coat finish provides better traction for safety and helps to increase productivity. This durable finish also provides better corrosion protection and adhesion compared to wet paint

- Compliant with ANSI MH30.1-2022 which includes rigorous load testing requirements

- Compared to paint, our powder coat process has major environmental advantages

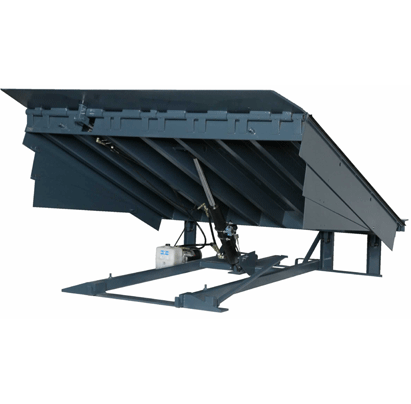

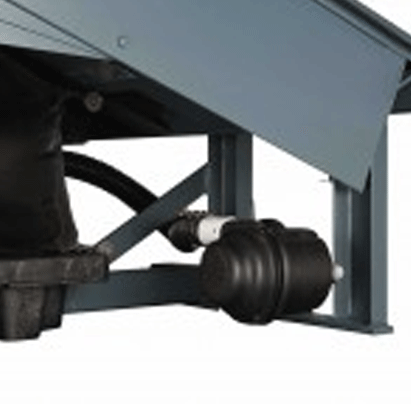

Hydraulic Pit Leveler – Models H68R & H78R

Built for Performance. Designed for Installers.

The Hydraulic Pit Leveler is a loading dock solution designed to enhance safety and efficiency in material handling operations. Featuring a hydraulic system, it offers smooth and reliable operation, reducing manual effort and potential injuries. Its durable construction ensures longevity, making it suitable for various industrial applications. This pit leveler seamlessly bridges the gap between the loading dock and trailers, facilitating safe and efficient loading and unloading processes.

1-Year Limited Warranty; 2-Year Limited Warranty when Overhead Door™ brand door and Hydraulic Pit Leveler purchased together.

MA SERIES AIR POWERED LEVELERS

MA Series

Air-Powered Dock Levelers

The MA Series air-powered dock leveler offers smooth push-button pneumatic operation with the strength and reliability needed for light to heavy-duty applications. Designed as an efficient alternative to hydraulic levelers, it provides durability, safety, and ease of maintenance.

RRH SERIES RAIL RAMP HYDRAULIC LEVELER

RRH Series Rail Ramp Hydraulic Leveler

Heavy-Duty Hydraulic Dock Solution for Rail Applications

The RRH Series Rail Ramp Hydraulic Leveler is engineered for high-demand rail dock operations, delivering effortless push-button activation with superior toughness and reliability. It is designed for seamless integration and can be mounted on the dock wall or recessed in a short pit, offering operational flexibility and low ownership costs.

Steel Dock Board (SC)

Steel Dock Board (SC)

Durable and Cost-Effective Dock Solution

The Steel Dock Board (SC) is a sturdy and economical choice for safe and efficient loading. Designed for use with forklifts, it features an all-welded steel construction, ensuring durability and long-lasting performance. Locking legs provide secure positioning, while included lifting chains enhance ease of handling. Ideal for warehouses and loading docks, this dock board offers reliable support for heavy loads.

Steel Dock Board (TFL-SB)

Steel Dock Board (TFL-SB)

Speedy Board™ – Effortless Positioning, Maximum Safety

The Steel Dock Board (TFL-SB) combines the strength of a "T" designed board with the convenience of a fixed-leg option. Enhanced with the Speedy Board™ feature, it includes fork cutouts on the leading edge, allowing forklift operators to scoop, position, and retrieve the board without leaving the safety of the forklift cage. Designed for efficient dock loading, this innovation streamlines operations while maintaining safety.

SB Option can be added to TFL, TNB, and SC boards at no charge.

Not recommended for below-dock loading.