Portable Steel Yard Ramp

The yard ramp allows for traffic to move from the dock level down to the ground or from the ground up into the back of a truck, which helps loading/unloading flow smoothly. The 18” industrial solid rubber pneumatic tires allow for easy movement of the ramp around your shipping yard to have you ready in minutes to begin loading/unloading. The hydraulic adjustment system permits fast reliable height adjustment of the yard ramp with virtually any trailer bed height.

Categories: Dock Levelers, Specialty Levelers

PRODUCT DOCUMENTS

Related products

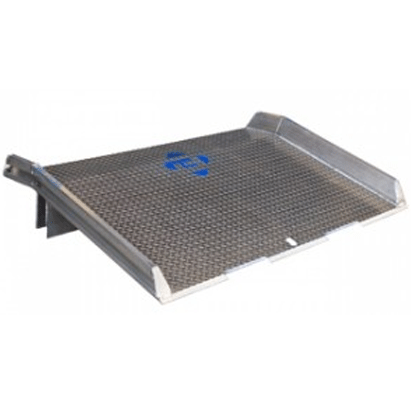

All Aluminum Welded Truck Dock Board (ATD)

- All Aluminum Welded Truck Dock Board (ATD) The All Aluminum Welded Truck Dock Board (ATD) is a lightweight yet durable solution for low to medium-volume loading applications. Designed for use with forklifts and pallet jacks, it features all-welded aluminum construction for strength and reliability. This innovative alternative to heavy-duty steel dock boards ensures efficient and safe loading operations.

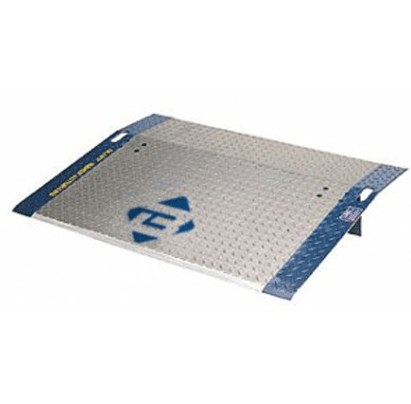

Aluminum Dock Plate (A-B)

Aluminum Dock Plate (A-B)

The Aluminum Dock Plate (A-B) is a cost-effective solution for light dock loading activities. It is designed specifically for non-powered dock-loading applications such as pallet trucks. It is built for efficiency and provides a smooth transition between the dock and the trailer with machine-beveled deck edges.

Aluminum Walk Ramps – Hook Style

Aluminum Walk Ramps – Hook Style

Lightweight, Durable, and Secure for Efficient Loading

Bluff’s Aluminum Walk Ramps – Hook Style provides a portable and secure solution for easily loading and unloading cargo. These ramps are designed for versatility and safety, ideal for warehouses, delivery services, and industrial applications.

Aluminum Wheel Risers (AWR)

Mechanical Pit Leveler M68R & M78R

- Fast, safe install with height adjusters operated while standing on building floor-no need for installer to be under leveler and no shimming/welding needed in rear of pit

- Adjusters quickly position the dock level with the building floor Improved safety — the installer is never under the leveler

- Levelers ship with four steel fork loops bolted to the deck, which improves stability when lifting from a truck. The loops help with forklift placement into a pit from inside or outside the building, and helps to minimize levelers sliding while stacked on top of each other

- Cut outs identify weld points to the curb angle for faster installation

- Lifter arm is mounted to the rear of the frame instead of sitting on pit floor. No need to shim or weld under the lifter arm

- Base frame is open all the way to the rear of the pit for easy access with no cross beams or places to trap debris

- C-channel beams create a strong deck structure and allows moisture to dry

- Deck design eliminates the transition angle which is a frequent repair on many levelers

- Deck hinge is fully supported across the entire width of the deck to enhance long term durability

- Durable textured powder coat finish

- Compliant with ANSI MH30.1-2022

- Designed with an optimized beveled lip to reduce bumps and damage to cargo and material handling equipment

- Reduces shocks and jolts to workers by creating a level pathway

- Facilitates fast movement of material handling equipment and forklifts

- Release chain for deck operation is user friendly and easy to pull

- The hold down is easy to operate

- Leveler is well-balanced for quick, easy articulation and automatically maintains positive lip contact with trailer movements

- The snubber chain and maintenance brace are positioned at side edges allowing easy access to the pit for maintenance and cleaning

MP SERIES MECHANICAL LEVELERS

MP Series Mechanical Levelers

Reliable, Cost-Effective Dock Leveling

The MP Series Mechanical Leveler offers smooth, dependable operation with a finger-tip release pull chain activation. Engineered for budget-friendly durability, it features a cam and roller counterbalance system for effortless walk-down to the trailer bed, with below-dock capability included. The floating hold-down design adapts to air ride trailers, while the full-width rear compression hinge enhances strength and longevity.

Steel Dock Board (TFL)

Steel Dock Board (TFL)

Reliable Strength with Locking Leg Stability

The Steel Dock Board (TFL) features the same heavy-duty design as the “T” dock board but utilizes locking legs instead of steel pins for secure positioning. This design ensures stability and ease of use, making it an excellent choice for standard dock loading operations.

Not recommended for below-dock loading.

VSH SERIES VERTICAL STORING HYDRAULIC LEVELER

VSH Series Vertical Storing Hydraulic Leveler

Optimized for High-Security and Temperature-Controlled Dock Operations

The VSH Series Vertical Storing Hydraulic Leveler is engineered for demanding dock environments, providing push-button operation, exceptional durability, and low maintenance costs. Its vertical storing design enhances climate control, security, and facility cleanliness, making it ideal for temperature-sensitive and high-security applications.