Edge of Dock Leveler E66R & E72R

Smooth Building-To-Truck Transition

- Designed to minimize bumps, gaps and damage to cargo and material handling equipment

- Reduces shocks and jolts to workers

- Facilitates fast movement of material handling equipment and forklifts

Easy and Safe Deployment

- Handle is easy to push/pull for comfortable and fast operation

- Handle range of motion keeps workers in a comfortable position

- Reduces bumps and trip hazards on deck and lip

Durable Design and Finish

- Rugged construction of lip and deck hinge provides durability for years of service

- Lip hinge sheds debris minimizing trapping and grinding between the lip deck junction causing fatigue

- Textured powder coat finish provides better traction for safety and helps to increase productivity. This durable finish also provides better corrosion protection and adhesion compared to wet paint

- Compliant with ANSI MH30.1-2022 which includes rigorous load testing requirements

Environmentally Friendly

- Compared to paint, our powder coat process has major environmental advantages

Categories: Dock Levelers, Edge of Dock Leveler

Features

Quick Unloading on a Smooth Path

- Smooth path allows forklift to move quickly over the leveler without bumps or jolts

- Optimized lip bevel provides a smooth roll over path from the trailer to the leveler

Easy-to-Use and Ergonomic

- Handle is quick and easy for workers to push/pull with a convenient built-in-storage receptacle and is tethered so it never gets lost

Ultimate Safety

- Minimal bumps or gaps on deck/lip for workers to trip over

- Proprietary powder coat formulation is textured to provide enhanced traction and non-slip protection. This is also helpful in wet or rainy conditions where non-textured surfaces can become slippery and dangerous or dangerous when wet

- Handle range of motion keeps workers in a comfortable position to help prevent injuries

- The edge of dock automatically returns to stored position to prevent hazardous conditions

Durability, Low Maintenance, Low Downtime

- Heavy duty multi-lug construction sheds debris instead of trapping/grinding it between the lip/deck junction and causing fatigue and maintenance issues

- Factory-applied powder coat material for increased durability and corrosion resistance compared to paint

Environmentally Friendly

- Our powder coat process has minimal Volatile Organic Compounds (VOCs) and solvents

- Overspray is recycled which reduces waste disposal issues compared to a paint process

- The US Environmental Protection Agency (EPA) recommends powder coatings as a sustainable coating option

Serviceability and Installation

- Field serviceable with easy to reach adjusters for springs and kicker bar

- Serviceable lip and hinge pin can be removed without breaking welds

- Service brace is easy to reach under the leveler and tethered so it never gets lost

- Grease fittings to lubricate deck hinge for smooth operation

| MODEL | SIZE | WEIGHT CAPACITY |

|---|---|---|

| E66R | 66" | 20,000 Ibs. 30,000 Ibs. |

| E72R | 72" | 20,000 Ibs. 30,000 Ibs. |

| BUMPERS | STANDARD | OPTIONAL |

| Molded bumpers | ✓ | |

| Bumper boxes | ✓ | |

| LIP | ||

| 15" lip | ✓ | |

| 17" lip | ✓ | |

| Lip bevel | ✓ | |

| OPERATION | ||

| Auto return to store | ✓ | |

| Self storing handle | ✓ | |

| Service brace | ✓ | |

| Safety tread on deck and lip | ✓ | |

| Working range 3" above/below dock | ✓ |

Documents

Related products

“HP” SERIES STANDARD DUTY HYDRAULIC

Pit Style Hydraulic Dock Leveler

The HP Series hydraulic dock leveler is designed with dependability and toughness in mind for your medium to lighter duty applications. The “HP” offers the same easy push button smooth, consistent operation as the heavy duty H series and the same built in safety, durability and toughness. Easy clean out and servicing are features of all McGuire levelers. Your budget, your safety and trouble free service are always number one with McGuire. They are also most often mounted in a pre-formed pit at the dock commonly used to reduce the grade between the dock floor and the trailer bed. Various sizes and capacities allow for a large amount of flexibility. Hydraulic levelers have added safety features and save time in operation and maintenance.

This series comes in 6’, 6’6” & 7’ standard widths and 6’, 8’ & 10’ standard lengths with 12’ and other lengths available. Standard capacities are 25K, 30K, 35K and 40K CIR (Comparative Industry Rating).

Container Ramps

Edge of Dock Leveler – Mounting Options

The Edge of Dock Leveler offers seamless functionality, engineered to optimize your dock’s performance. Paired with the right mounting option, it ensures smooth transitions, reinforced stability, and long-term reliability—no matter the working environment. From reducing downtime to improving safety, our mounting solutions elevate your operation’s efficiency.

Whether you need smooth building-to-truck transitions, stable vertical mounting, or easy concrete integration, we have a solution for you.

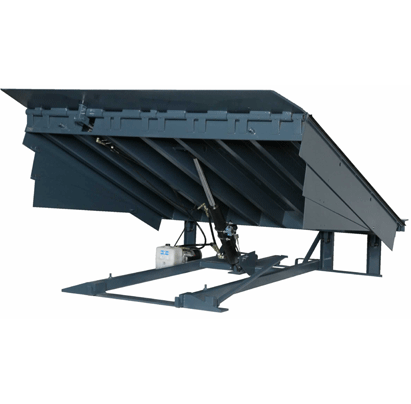

H SERIES AUTODOK® HEAVY DUTY HYDRAULIC

Pit Style Hydraulic Dock Leveler

The “H” Series hydraulic dock leveler is structurally designed for the most demanding applications with easy push button convenience for smooth, consistent operation plus outstanding toughness and dependability in your most challenging dock operations. McGuire offers a hydraulic dock leveler to meet any of your dock equipment needs while providing low lifetime ownership costs and years of trouble free service with the industry’s best built-in safety. They are most often mounted in a pre-formed pit at the dock commonly used to reduce the grade between the dock floor and the trailer bed. Various sizes and capacities allow for a large amount of flexibility. Hydraulic levelers have added safety features and save time in operation and maintenance.

The H Series comes in 6’, 6’6” & 7’ standard widths and 6’, 8’ & 10’ standard lengths with 12’ and other lengths available. Standard capacities for the “H” Series are 45K, 55K, 75K and 100K CIR (Comparative Industry Rating).

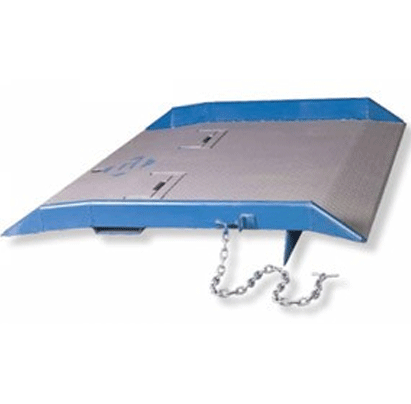

MP SERIES MECHANICAL LEVELERS

MP Series Mechanical Levelers

Reliable, Cost-Effective Dock Leveling

The MP Series Mechanical Leveler offers smooth, dependable operation with a finger-tip release pull chain activation. Engineered for budget-friendly durability, it features a cam and roller counterbalance system for effortless walk-down to the trailer bed, with below-dock capability included. The floating hold-down design adapts to air ride trailers, while the full-width rear compression hinge enhances strength and longevity.

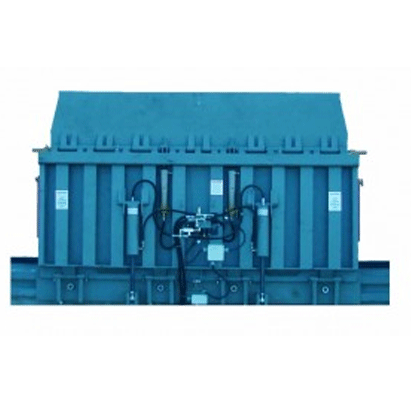

RRH SERIES RAIL RAMP HYDRAULIC LEVELER

RRH Series Rail Ramp Hydraulic Leveler

Heavy-Duty Hydraulic Dock Solution for Rail Applications

The RRH Series Rail Ramp Hydraulic Leveler is engineered for high-demand rail dock operations, delivering effortless push-button activation with superior toughness and reliability. It is designed for seamless integration and can be mounted on the dock wall or recessed in a short pit, offering operational flexibility and low ownership costs.

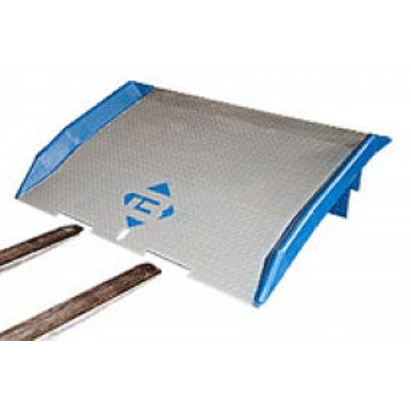

Steel Dock Board (TFL-SB)

Steel Dock Board (TFL-SB)

Speedy Board™ – Effortless Positioning, Maximum Safety

The Steel Dock Board (TFL-SB) combines the strength of a "T" designed board with the convenience of a fixed-leg option. Enhanced with the Speedy Board™ feature, it includes fork cutouts on the leading edge, allowing forklift operators to scoop, position, and retrieve the board without leaving the safety of the forklift cage. Designed for efficient dock loading, this innovation streamlines operations while maintaining safety.

SB Option can be added to TFL, TNB, and SC boards at no charge.

Not recommended for below-dock loading.