Mechanical Pit Leveler M68R & M78R

- Fast, safe install with height adjusters operated while standing on building floor-no need for installer to be under leveler and no shimming/welding needed in rear of pit

- Adjusters quickly position the dock level with the building floor

Improved safety — the installer is never under the leveler - Levelers ship with four steel fork loops bolted to the deck, which improves stability when lifting from a truck. The loops help with forklift placement into a pit from inside or outside the building, and helps to minimize levelers sliding while stacked on top of each other

- Cut outs identify weld points to the curb angle for faster installation

- Lifter arm is mounted to the rear of the frame instead of sitting on pit floor. No need to shim or weld under the lifter arm

Durable Design and Finish

- Base frame is open all the way to the rear of the pit for easy access with no cross beams or places to trap debris

- C-channel beams create a strong deck structure and allows moisture to dry

- Deck design eliminates the transition angle which is a frequent repair on many levelers

- Deck hinge is fully supported across the entire width of the deck to enhance long term durability

- Durable textured powder coat finish

- Compliant with ANSI MH30.1-2022

Smooth Building-To-Truck Transition

- Designed with an optimized beveled lip to reduce bumps and damage to cargo and material handling equipment

- Reduces shocks and jolts to workers by creating a level pathway

- Facilitates fast movement of material handling equipment and forklifts

Easy-to-Use and Ergonomic

- Release chain for deck operation is user friendly and easy to pull

- The hold down is easy to operate

- Leveler is well-balanced for quick, easy articulation and automatically maintains positive lip contact with trailer movements

- The snubber chain and maintenance brace are positioned at side edges allowing easy access to the pit for maintenance and cleaning

Categories: Dock Levelers, Hydraulic Levelers

Features

Installer Friendly

Safety Focus

- Installers are never under the pit

- Minimal bumps or gaps on deck/lip reduce trip hazards for workers

- Proprietary powder coat formulation on deck and lip surfaces is textured to provide enhanced traction and non-slip protection even when wet

Durability, Low Maintenance, Low Downtime

- Heavy duty multi-lug construction of the lip hinge. The design helps shed debris instead of trapping/grinding it between the lip/deck junction that can cause fatigue and maintenance issues. The lug construction also allows for easy lubrication of the hinge.

- Deck hinge is fully supported across the entire width of the deck, which spreads the load across the width of the deck instead of concentrating the load on just a few hinge points

- Durable textured powder coat provides an extremely durable finish, better corrosion protection and adhesion compared to wet paint

- Complies with ANSI MH30.1-2022 that includes rigorous load testing requirements

- Deck Thickness ¼ inch

- Lip Thickness 5/8 inch 30/35K, ¾ inch 40/45K

Environmentally Friendly

- Our powder coat process has fewer Volatile Organic Compounds (VOCs) and solvents compared to paint

- Overspray is recycled which reduces waste disposal issues compared to a traditional paint process

The US Environmental Protection Agency (EPA) recommends powder coatings as a sustainable coating option

Installation and Serviceability

- Open base frame creates generous space for service along the full length of the leveler, including the rear which is the most difficult area to reach for cleaning and a common collection point for debris

- Leveler main springs are tightened/loosened with one adjustment point conveniently located on lift arm

- Field serviceable with easy to reach adjuster for main spring

- Serviceable lip and hinge pin can be removed without breaking welds

- Maintenance brace is easy to reach under the leveler and is tethered so it never gets lost. Brace holds leveler up by the deck to allow lip maintenance

- Leveler ships with four forklift lifting loops bolted to deck, allowing leveler to be lifted from the front or rear for easy transport and placement in the pit

MODEL M68R

| WEIGHT CAPACITY | DIMENSION (NOMINAL) | |

|---|---|---|

| 30,000, 35,000, 40,000, and 45,000 lbs. | Model M68R: 6' W x 8' L Model M78R: 7' W x 8' L |

|

| BUMPERS | STANDARD | OPTIONAL |

| Laminated Bumpers 410-14 W1 |

✓ | |

| Laminated Upgraded Bumpers 410-14 W2, 412-14 W1/W2, 610-14 W1/W2, V420-11 W1/W2, V620-11 W1/W2, V624-11 W1/W2 |

✓ | |

| Steel Face Bumpers 410-14 SF W1/W2, 610-14 SF W1/W2 |

✓ | |

| CONTROL | ||

| Hold Down A/R | ✓ | |

| Working Range 12" Above/Below Dock | ✓ | |

| FINISH | ||

| Gray Powder Coat | ✓ | |

| LIP | ||

| 16" Lip | ✓ | |

| 18" & 20" Lip | ✓ | |

| Lip Keepers | ✓ | |

| Lip Bevel | ✓ | |

| Lip Taper (Model M78R only) | ✓ | |

| SAFETY | ||

| Safety Legs | ✓ | |

| Maintenance Brace | ✓ | |

| Safety Tread on Deck and Lip | ✓ | |

| Toe Guards: Working Range | ✓ | |

| Toe Guards: Full Operating Range | ✓ | |

| TRANSPORT | ||

| Reinforced Lifting Bolt Holes in Deck (4) | ✓ | |

| Steel Lifting Loops (Bolt to Deck) (4) | ✓ | |

| WEATHER SEALS | ||

| Weather Seal: Brush | ✓ | |

| Weather Seal: Neoprene | ✓ | |

| Chain Hole Seal | ✓ | |

1-Year Limited Warranty; 2-Year Limited Warranty when Overhead Door™ brand door and Mechanical Pit Leveler purchased together.

Documents

Related products

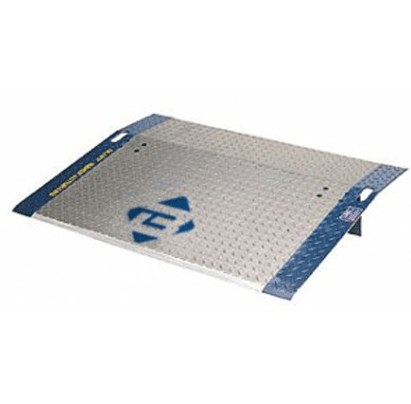

Aluminum Dock Plate (A-B)

Aluminum Dock Plate (A-B)

The Aluminum Dock Plate (A-B) is a cost-effective solution for light dock loading activities. It is designed specifically for non-powered dock-loading applications such as pallet trucks. It is built for efficiency and provides a smooth transition between the dock and the trailer with machine-beveled deck edges.

Aluminum Walk Ramps – Apron Style

Aluminum Walk Ramps – Apron Style

Lightweight, Portable, and Built for Safety

Bluff’s Aluminum Walk Ramps—apron Style—offer a strong yet lightweight solution for efficiently loading and unloading cargo. Designed for portability and convenience, these ramps are perfect for warehouses, delivery services, and industrial settings.

Edge of Dock Leveler – Mounting Options

The Edge of Dock Leveler offers seamless functionality, engineered to optimize your dock’s performance. Paired with the right mounting option, it ensures smooth transitions, reinforced stability, and long-term reliability—no matter the working environment. From reducing downtime to improving safety, our mounting solutions elevate your operation’s efficiency.

Whether you need smooth building-to-truck transitions, stable vertical mounting, or easy concrete integration, we have a solution for you.

H SERIES AUTODOK® HEAVY DUTY HYDRAULIC

Pit Style Hydraulic Dock Leveler

The “H” Series hydraulic dock leveler is structurally designed for the most demanding applications with easy push button convenience for smooth, consistent operation plus outstanding toughness and dependability in your most challenging dock operations. McGuire offers a hydraulic dock leveler to meet any of your dock equipment needs while providing low lifetime ownership costs and years of trouble free service with the industry’s best built-in safety. They are most often mounted in a pre-formed pit at the dock commonly used to reduce the grade between the dock floor and the trailer bed. Various sizes and capacities allow for a large amount of flexibility. Hydraulic levelers have added safety features and save time in operation and maintenance.

The H Series comes in 6’, 6’6” & 7’ standard widths and 6’, 8’ & 10’ standard lengths with 12’ and other lengths available. Standard capacities for the “H” Series are 45K, 55K, 75K and 100K CIR (Comparative Industry Rating).

MP SERIES MECHANICAL LEVELERS

MP Series Mechanical Levelers

Reliable, Cost-Effective Dock Leveling

The MP Series Mechanical Leveler offers smooth, dependable operation with a finger-tip release pull chain activation. Engineered for budget-friendly durability, it features a cam and roller counterbalance system for effortless walk-down to the trailer bed, with below-dock capability included. The floating hold-down design adapts to air ride trailers, while the full-width rear compression hinge enhances strength and longevity.

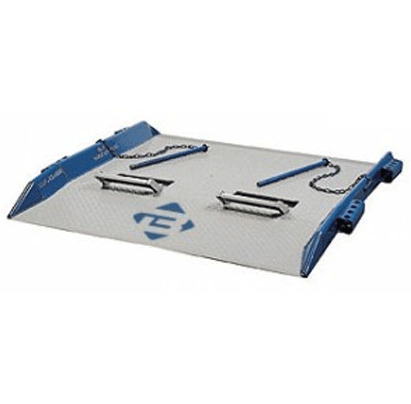

Red Pin Steel Dock Board (C)

Steel Dock Board (T)

Steel Dock Board (T)

Heavy-Duty Stability for Secure Docking

The Steel Dock Board (T) is built for demanding loading environments, offering unmatched strength and stability. Featuring an all-welded steel construction, it is secured in place using two 1" stress-proof steel pins, preventing slippage during operation. Its double-bend design allows for seamless adaptability to various trailer types, including conventional, refrigerated, and container trailers. With fold-down lifting loops for easy transport and multiple pin hole locations for precise positioning, this dock board ensures safe and efficient loading.