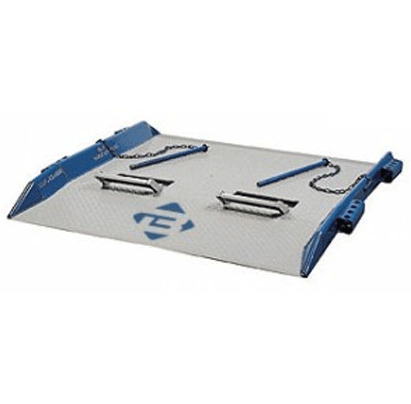

Steel Dock Board (TFL)

Steel Dock Board (TFL)

Reliable Strength with Locking Leg Stability

The Steel Dock Board (TFL) features the same heavy-duty design as the “T” dock board but utilizes locking legs instead of steel pins for secure positioning. This design ensures stability and ease of use, making it an excellent choice for standard dock loading operations.

Not recommended for below-dock loading.

Categories: Dock Boards, Dock Levelers

Description

Description

Features

• All-welded steel construction

• Locking legs for secure placement

• Designed for conventional dock loading

Related products

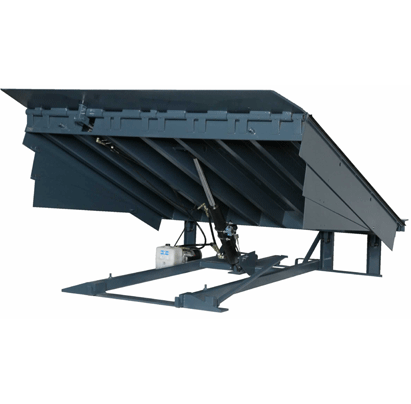

“HP” SERIES STANDARD DUTY HYDRAULIC

Pit Style Hydraulic Dock Leveler

The HP Series hydraulic dock leveler is designed with dependability and toughness in mind for your medium to lighter duty applications. The “HP” offers the same easy push button smooth, consistent operation as the heavy duty H series and the same built in safety, durability and toughness. Easy clean out and servicing are features of all McGuire levelers. Your budget, your safety and trouble free service are always number one with McGuire. They are also most often mounted in a pre-formed pit at the dock commonly used to reduce the grade between the dock floor and the trailer bed. Various sizes and capacities allow for a large amount of flexibility. Hydraulic levelers have added safety features and save time in operation and maintenance.

This series comes in 6’, 6’6” & 7’ standard widths and 6’, 8’ & 10’ standard lengths with 12’ and other lengths available. Standard capacities are 25K, 30K, 35K and 40K CIR (Comparative Industry Rating).

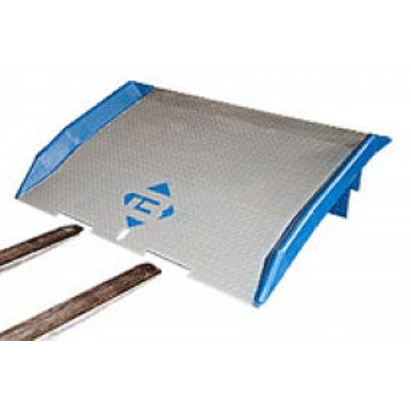

Aluminum Dock Board

Aluminum Dock Board

The Aluminum Dock Board is designed for secure and efficient loading operations. It features a durable aluminum diamond pattern plate reinforced with full-length structural steel bolt-on curbs. This combination enhances strength and prevents runoff, ensuring safety and reliability in dock loading applications.

Aluminum Walk Ramps – Hook Style

Aluminum Walk Ramps – Hook Style

Lightweight, Durable, and Secure for Efficient Loading

Bluff’s Aluminum Walk Ramps – Hook Style provides a portable and secure solution for easily loading and unloading cargo. These ramps are designed for versatility and safety, ideal for warehouses, delivery services, and industrial applications.

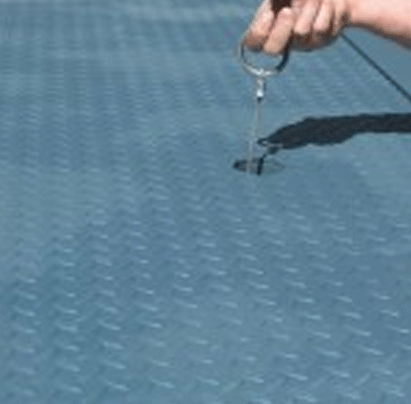

CENTRAAIR® SERIES AIR POWERED LEVELERS

CentraAir® Series

Air-Powered Dock Levelers

The CentraAir® Series air-powered dock leveler utilizes common plant air and an industrial-grade air bellows system for smooth, push-button operation. Designed for efficiency and ease of use, it can also be manually activated via a lanyard control. Built for durability and safety, it offers easy clean-out and servicing while reducing the grade difference between the dock floor and trailer bed.